The aviation industry globally accounts for approximately 2% of the total greenhouse gas emissions. Consequently, the sector is dedicated to finding solutions to reduce the climate impact of air transportation, which is expected to increase year by year.

The growing demand for global air transport also means an increase in the industry’s greenhouse gas emissions. This development amplifies the necessity for the aviation sector to take action to meet the goals outlined in the Paris Agreement. In this context, new and progressively more sustainable aircraft fuels must play a pivotal role in reducing the environmental impact. However, optimisations and enhancements in operations, infrastructure, as well as the development of new technology are also crucial in reducing emissions in aviation.

Therefore, DCC & Shell Aviation Denmark is currently engaged in Green Power Denmark’s PtX partnership. Additionally, we support Arcadia eFuels’ ambitions for PtX production in Vordingborg and a development project at Aalborg University, where wastewater sludge and wood waste are converted into more sustainable fuels for air and maritime transportation.

How we optimise our operations

In Denmark, DCC & Shell Aviation has long been dedicated to optimizing and improving our daily operations and infrastructure.

At Billund and Copenhagen Airports, our refuelers and dispensers currently operate on the biofuel HVO (Hydrotreated Vegetable Oil). Very soon, we will introduce the first electric-powered refueler as a step toward electrifying our fleet at the airports.

At the other Danish airports, our tanker trucks today use the natural gas-based GTL (Gas-to-Liquid) fuel. GTL burns cleaner than regular diesel, contributing to improved working conditions for our employees and preventing operational disruptions.

SAF

The greatest potential for reducing CO2 emissions in the aviation industry is to replace fossil jet fuel with more sustainable fuels. This is currently happening with Sustainable Aviation Fuel (SAF). SAF is an umbrella term for alternative aviation fuels made from more sustainable sources, typically waste biomass such as waste cooking oil. One significant advantage of SAF is its seamless integration into the global aircraft fleet and existing fuel infrastructure in and around airports.

The pure component of SAF is also called Synthetic Paraffinic Kerosene (SPK), but it has yet to be approved by engine manufacturers for full use. Consequently, SAF is also called a drop-in fuel and currently subject to a maximum blending ratio of 50% with conventional JET A-1. Airbus and GE Aviation, among others, are, however, testing flights on 100% pure SAF. At a 50/50 blend ratio, SAF is classified as JET A-1 and is identical to the fossil-derived JET A-1.

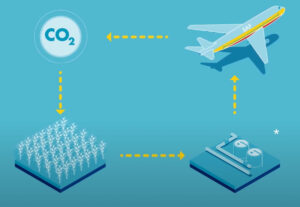

How SAF reduces CO2 emissions

The recycling of waste biomass into fuel is a major step in reducing aviation CO2 emissions. When, for example, recycled cooking oil is used for aviation fuel, such fuel is effectively considered CO2 neutral.

That is because the cooking oil is derived from plants having absorbed CO2 equal to the amount emitted by the combustion of the fuel. As the combustion is part of a circular, biological system, where it becomes available to new plants, no more CO2 is, in principle, added.

However, the production and transport of SAF and waste biomass still emit CO2. Taking the entire life cycle into consideration, SAF emits about 80% less CO2 than fossil aviation fuel.

The SAF supplied by DCC & Shell Aviation to, for example, Sonderborg Airport and Alsie Express is produced by one of the world’s leading producers of bio-based fuels, Finnish Neste.

Ny teknologi driver luftfartens reduktioner

De kommende år og årtier vil nye teknologier og energiformer spille en central rolle i at gøre luftfarten fri af fossile brændstoffer. Allerede nu bliver hver ny generation af fly mere effektive og brændstoføkonomiske. Og da brændstoffet er den primære årsag til luftfartens CO2-udledning, er det en vigtig udvikling.

Men særligt vil det at erstatte fossilt flybrændstof med low carbon og på sigt no carbon-alternativer få enorm betydning for en mere bæredygtig flyindustri. Samtidig arbejder fly- og motorfabrikanterne målrettet med teknologi både til at elektrificere fly og til at benytte renere, alternative brændstoffer som flydende brint. Det er dog en indsats, der kræver massive udviklingsinvesteringer og etablering af en ny infrastruktur i lufthavne.

Power in the form of liquid fuel – Power-to-X

Aircraft electrification is today limited by the weight, size, and relatively restricted energy capacity of batteries. Therefore, electric propulsion is primarily expected to be relevant for regional airliners.

Both short and medium-haul aircraft hold significant potential for green hydrogen or fuel cells. Such technology, today known as Power-to-X, holds the greatest potential for reducing the aviation industry’s carbon footprint. Power-to-X is a highly advanced process that converts green energy from sources like wind, solar, or water into liquid fuel, such as aviation fuel. This conversion occurs within an electrolysis plant where green energy splits water (H2O) into H2/green hydrogen and O/oxygen.

The hydrogen can then either be used directly as fuel or converted into liquid fuel through a carbonisation process requiring biogen CO2. Biogen CO2 can be sourced from biogas plants or extracted from the atmosphere, known as Direct Air Capture (DAC). The carbon (C) from CO2 is combined with green hydrogen to form C-H compounds, which eventually can become, for example, green aviation fuel. Large-scale Power-to-X production and safe handling of liquid hydrogen require significant investments and continuous development, in which Denmark stands among the leaders in this context.

Book & Claim: Integrating SAF into the infrastructure

A massive deployment of SAF and later Power-to-X-based aviation fuels in Denmark and internationally requires a sustainable and stable supply chain that integrates with the existing fuel infrastructure. The alternative would involve establishing an entirely new infrastructure alongside the existing one, dedicated solely to handling SAF, etc. Such a solution would significantly increase carbon emissions and create impractical, cost-intensive logistics.

This is where the Book & Claim principle comes into play. Book & Claim resembles the model we are familiar with from green energy in the Danish electricity grid, where the purchase of green electricity, or in this context SAF, occurs separately from the physical product. Essentially, the customer “claims” a specific portion of a total pool of SAF that has already been supplied into the fuel infrastructure of the Danish aviation. The supplier books this purchase in the system, issuing a unique certificate to guarantee the customer’s delivery and ensuring that the same quantity of SAF is only sold once.

In a future where SAF is expected to constitute a larger share of fuel supplies, the Book & Claim model is both sustainable and realistic from a logistical standpoint. Unlike today, when DCC & Shell Aviation Denmark supplies SAF directly to individual customers because we are in the early stages of development. This solution will not be feasible when delivering significantly larger quantities across the country to airports and private clients.

Instead, SAF will be supplied to the fuel system at specific airports. The quantity will then be registered and verified, following which the specific CO2 emissions from the fuel will be calculated. Customers’ specific purchases and consumption of SAF, along with the resulting reduction in emissions, will subsequently be certified based on the total quantity.

There is still a need for broader acceptance and adoption of Book & Claim as the general, unifying model to monitor and manage a large-scale rollout of SAF globally. However, initiatives like Shell’s collaboration with Accenture and American Express on a digital book & claim represent steps in this direction.